- Engineering Organization Providing Solutions for Industries

Email: info@utslanka.com, sales@utslanka.com

Ribbon Blending Powder Mixer / Ribbon Blender

The Horizontal Ribbon Mixer consist of U-Shape tank, spiral and drive parts. The spiral is dual structure. Outer spiral make the material move from the sides to the center of the tank and the inner screw conveyor the material from the center to the sides to get the convective mixing. Our TDPM series Ribbon mixer can mix many kinds material especially for the powder and granular which with stick or cohesion character, or add a little liquid and paste material into powder and granular material. The mixture effect is high. The cover of the tank can be made as open in order to cleaning and change parts easily.

Optional:

The top cover of the U Shape tank has the entrance for material. It can be also designed with spray or add liquid device according the customer’s needs. This mixer also can be designed with the function to keep cold or heat. Add one layer outside the tank and put into medium into the interlayer to get the mixing material cold or heat. Usually use water for cool and hot steam or use electrical for heat Both manual and pneumatic discharge way is available dust collector is optional

VERTICAL DRUM TYPE POWDER MIXER MACHINE (50KG/ BATCH) POWER: 2.2KW

Double Cone Powder Mixing Machine

SZH series double cone mixer/blender is most often used for the intimate dry mixing of free flowing solids. The materials are fed into the mixing chamber via quick-open feed port manually or by vacuum conveyor. With the rotation of mixing chamber, materials are completely mixed with high degree of homogeneity. Normal cycle times are typically in the range of 10 minutes; however they can be less depending on the difficulty of mixing.

SZH series double cone mixer/blender is widely used in pharmaceutical, nutriceutical, chemical and food industries for mixing dry powder or small granules with good flowability. The solids being mixed can vary in bulk density and in percentage of the total mixture.

Technical Data Sheet

| Model | SZH-180 | SZH-300 | SZH-500 | SZH-1000 | SZH-1500 | VHJ-2000 |

| Volume L | 180 | 300 | 500 | 1000 | 1500 | 2000 |

| Capacity kg/batch | 40 | 60 | 100 | 200 | 300 | 400 |

| Mixing time Min | 4-8 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 |

| Rotation speed RPM | 12 | 12 | 12 | 12 | 10 | 10 |

| Motor power KW | 1.1 | 1.1 | 2.2 | 4 | 4 | 7.5 |

| Dimension LxWxH M | 1.4X0.8X1.8 | 1.7X0.8X1.9 | 1.9X0.8X2 | 2.8x1.5x2.4 | 2.9x1.5x2.5 | 3.4x1.9x3.5 |

| Totation height mm | 1850 | 1850 | 1950 | 2460 | 2540 | 3.650 |

| Weight kg | 280 | 310 | 550 | 810 | 980 | 2150 |

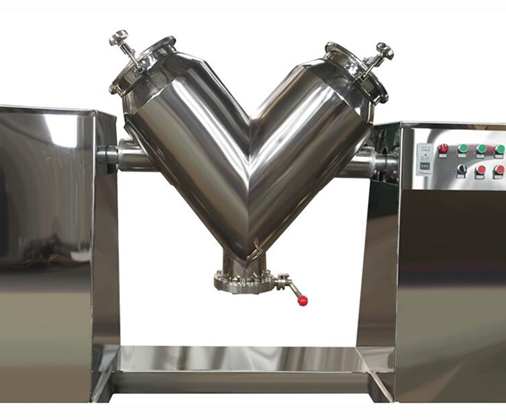

V - Type Powder Mixer

SZH series double cone mixer/blender is most often used for the intimate dry mixing of free V-type mixer is composed of two cylinder V-type container welded together; the shape of the container is non-symmetric relative to the axis. Since rotational movement, the powder continuously and alternately repeat, split, merge in the tilt cylinder. Material randomly passes from one area to another. While the powder or granular particlesslip, multiplestack in space. Repeated cutting, diffusion mixing.

Technical Data Sheet

| Model | Barrel volume(L) | Max load volume(L) | Motor (KW) | Overall size (mm) | Weight (KG) | Inlet size (mm) |

| BSV-100 | 100 | 60 | 1 | 1840(L)*600(W)*1430(H) | 230 | 2-∅220 |

| BSV-200 | 200 | 120 | 1.1 | 2110(L)*600(W)*1675(H) | 280 | 2-∅220 |

| BSV-300 | 300 | 180 | 1.5 | 2280(L)*630(W)*1780(H) | 320 | 2-∅280 |

| BSV-500 | 500 | 300 | 2.2 | 2655(L)*1040(W)*2200(H) | 550 | 2-∅325 |

| BSV-1000 | 1000 | 600 | 4 | 3070(L)*1240(W)*2490(H) | 850 | 2-∅350 |

| BSV-1500 | 1500 | 900 | 5.5 | 3070(L)*1240(W)*2490(H) | 1120 | 2-∅350 |

| BSV-2000 | 2000 | 1200 | 7.5 | 3900(L)*1440(W)*3100(H) | 2040 | 2-∅380 |

| BSV-2500 | 2500 | 1500 | 7.5 | 4000(L)*1500(W)*3225(H) | 2200 | 2-∅380 |

| BSV-3000 | 3000 | 1800 | 7.5 | 4370(L)*2000(W)*3560(H) | 2500 | 2-∅450 |

| BSV-4000 | 4000 | 2400 | 11 | 4800(L)*2000(W)*4000(H) | 2800 | 2-∅450 |

Menu

Products

contact us

- #10

Kadawtha Road ( Off Anderson Road),

Kalubowila,

Dehiwela,

Sri Lanka. - Call us now:+94 112 766 151

- Email: sales@utslanka.com